How to Spot a Counterfeit - When Minimum Testing Isn’t Enough

Damir Akhoundov

ERAI, Inc.

How to Spot a Counterfeit - When Minimum Testing Isn’t Enough

Many of the parts submitted to ERAI are reported after failing an external visual inspection, remarking and resurfacing testing or AC/DC electrical testing. In many cases companies continue to rely mainly on these tests, despite advances in counterfeiting techniques, because they are relatively inexpensive and do not require costly specialized equipment to perform. However, some nonconformances can only be uncovered using more advanced testing techniques such as decapsulation and electrical testing on a dedicated platform. Advanced testing may be necessary, dependent on application risk, which is why clear dialogue with your customer is key.

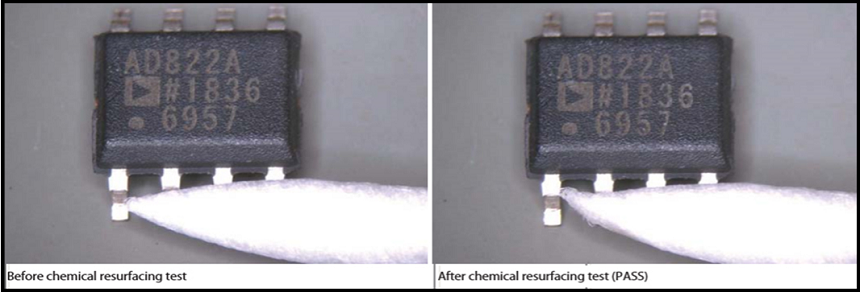

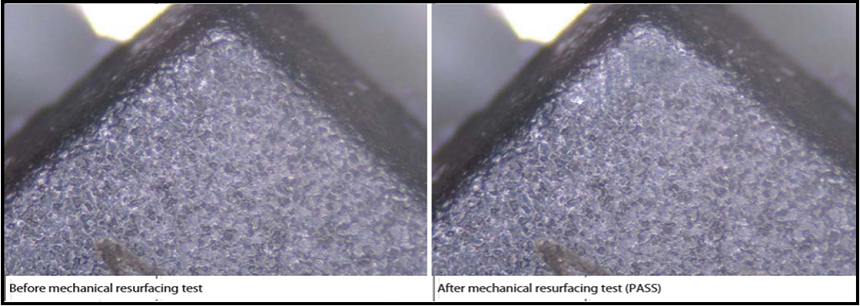

ERAI received an analysis report from an independent test lab which illustrates how extended testing can detect advanced counterfeits and cloned devices. The test laboratory received 50 pieces of Analog Devices part number AD822ARZ-REEL7 for inspection. The parts arrived in a coiled tape strip with ESD protective packaging. The parts were subjected to external visual inspection (EVI), and resurfacing testing. The parts were measured and were found to be within the manufacturer’s dimensional specifications. The devices displayed the same exterior configuration as shown on the Package Outline Drawing (POD). The leads displayed exposed base metal from trimming and stress marks from the forming process, which indicated that they were not re-plated. There were no solder remnants, scratches, or any other indications of prior use. All 50 pieces passed coplanarity analysis. Remarking and resurfacing tests, both chemical and mechanical scraping, revealed no evidence of remarking or resurfacing.

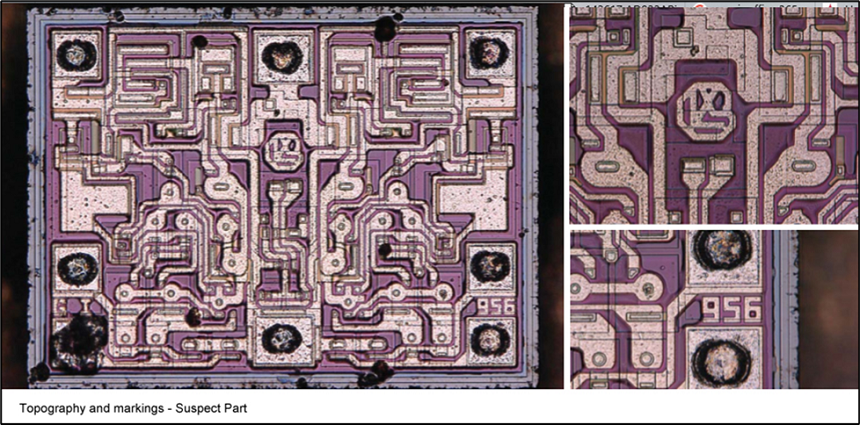

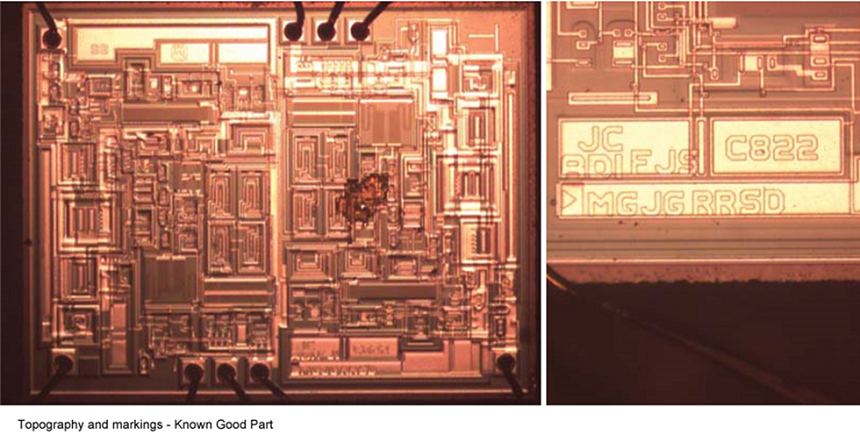

Five pieces were then subjected to X-ray and decapsulation analysis. The X-ray analysis revealed that the structures across the 5-piece sample were consistent and exhibited no voids or other abnormalities. The decapsulation analysis; however, revealed that a sample part showed an unknown logo die marking and 956 marking that was not traceable to Analog Devices or the specified part number. Die markings and die topography did not match those of a known good sample.

Subsequent electrical testing of 49 samples indicated that all pieces failed with low Vout or output voltage. ERAI was able to confirm that the die is not an Analog Device die.

While AC or DC electrical testing can confirm performance characteristics, many times only a small part of the die is covered. Complex parts can require in-depth test planning and development, which can result in long testing lead times and high costs. Many times, test laboratories have to develop their own solutions in the form of models or device simulators if they do not have support from the manufacturer to ensure that the part is operating to the manufacturer’s specifications. Device emulators can be used to simulate how a part will operate. By using a known good device configured for use in the final application, test vectors can be obtained that can be used for comparison to parts to be tested.

While developing a test strategy, you should keep in mind to test the performance characteristics of the design you are implementing and perform a risk assessment on the application. Working closely with a test lab to reduce unknowns and setting limits to your parameters allows you to control costs and avoid lengthy testing times. Remember that test labs can face lead times for hardware and testing sockets critical for testing, so it’s important to start the dialogue early in your process with your chosen test lab. You, as a supplier, must know and clearly understand your customer’s expectations. Keeping an open dialogue with your customer, suppliers and test labs is critical to your organization’s success in delivering quality product, whether your organization is supplying parts or a final product. As counterfeiters become more sophisticated, it is important that, regardless of the source of supply and, if risk analysis dictates, the highest level of due diligence must be applied during testing for authenticity verification.

SEE MORE BLOG ENTRIES

|