New InterCEPT Classes Launched

Kristal Snider

ERAI, Inc.

InterCEPT has launched two new classes to supplement your organization’s training requirements. Each class features handouts of the course material, quizzes, a final exam, and a certificate of completion that can easily be verified by an auditor or customer on ERAI’s website.

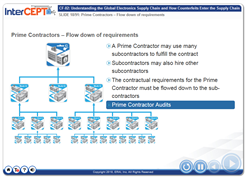

CF-02: Understanding the Global Electronics Supply Chain and How Counterfeits Enter the Supply Chain

A supply chain is a network between a company and its suppliers to produce and distribute a specific product. In the electronics industry, the supply chain represents the steps it takes to get the product from the original manufacturer to the customer. Supply chain activities include production, distribution, logistics and sourcing. Companies in a supply chain are often referred to as tiers. In this class we will examine the various tiers that make up the global semiconductor supply chain. From organizations who manufacture components (OCMs and Aftermarket Manufacturers), to authorized distributors and independent distribution, electronic parts can change hands several times, increasing the risk of encountering a counterfeit part.

This class:

- Explains the vital role each tier plays.

- Demonstrates the movement of parts through the use of real-world scenarios.

- Identifies vulnerabilities that may contribute to the introduction of a counterfeit part, which has the potential to seriously compromise the safety and operational effectiveness of products.

The course covers:

- Definition of the tiers of suppliers in the electronic supply chain (OCM, AD, ID, Broker)

- Electronics supply chain statistics from the Bureau of Industry and Security study

- Risk levels associated with each tier

- Definition of the tiers of customers in the electronic supply chain (OEM, CM)

- Supply chain transactions and their vulnerabilities

Students completing the class will be able to:

- Understand the vital role of each tier of the electronic supply chain.

- Distinguish the risk levels associated with different tiers of the supply chain.

- Identify vulnerabilities that may contribute to the introduction of a counterfeit part.

Click here to register for CF-02

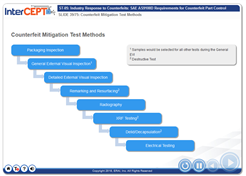

ST-05: Industry Response to Counterfeits: SAE AS9100D Requirements for Counterfeit Part Control

The International Aerospace Quality Group (IAQG) released SAE AS9100D - Quality Management Systems - Requirements for Aviation, Space, and Defense Organizations in September of 2016. Although counterfeit parts have been a concern in the military and aerospace industries for years, this version of SAE AS9100 includes requirements for counterfeit parts prevention. The class will provide background information and statistics about counterfeit electronic parts, discuss the requirements of SAE AS9100D as they relate to counterfeit parts and review several options for meeting those requirements. In addition, this class discusses several best practices including a documented counterfeit mitigation program, obsolescence management, the GIDEP (Government Industry Data Exchange Program) and ERAI databases which are repositories of counterfeit part information, and the InterCEPT training modules which can be used to meet the training requirements for SAE AS9100D.

The course covers:

-

General statistics about counterfeit electronic parts

- ERAI statistics

- Defense Industrial Base Assessment: Counterfeit Electronics

- Committee on Armed Services Senate Hearings: Inquiry into Counterfeit Electronic Parts in the Department of Defense Supply Chain

- GAO-12-375 - Suspect Counterfeit Electronic Parts can be Found on Internet Purchasing Platforms

- Overview of counterfeit parts requirements in AS9100D

- Relevant industry standards with a focus on counterfeit mitigation

-

Best practices in counterfeit mitigation

- Documented policy

- Obsolescence management

- GIDEP database

- ERAI database

- InterCEPT web-based training

Students completing the class will:

- Become familiar with the issue of counterfeit electronic parts.

- Understand the requirements in SAE AS9100D regarding counterfeit electronic parts.

- Become familiar with the relevant industry standards developed to address counterfeit electronic parts and materials.

- Identify best practices in the mitigation of counterfeit electronic parts in the supply chain.

- Review several options for handling the requirements of SAE AS9100D in your organization’s quality management system.

- Understand how the GIDEP database and the ERAI database are used to reduce the risk of purchasing or supplying a counterfeit part.

- Understand how InterCEPT web-based training can meet the requirements for training in AS9100D.

The class has been developed for individuals with auditing, contracting, management, purchasing, sales, quality and engineering roles.

Click here to register for ST-05

Launching soon – InterCEPT class TM-02: Counterfeit Inspection and Testing of Electronic Parts: Visual Inspection and Criteria for Acceptance or Rejection

This class will provide an in-depth discussion of external visual inspection associated with detecting counterfeit electronic parts. It will reference both the IDEA 1010B standard and the SAE AS6171 requirements for external visual inspection. The class includes video footage and images from a test lab to help the student understand how the visual inspection is performed. Device images will be reviewed so that the student can recognize the indicators of counterfeit or substandard electronic components and understand the criteria for acceptance and rejection.

The course covers:

-

External visual inspection

- Equipment needed, equipment costs

- How to perform the test including on-site video and step-by-step instructions

- Criteria for acceptance

- Criteria for rejection

- Content of test reports

- Training considerations

- Outsourcing visual inspection

Students completing the class will:

- Understand the terminology for external visual inspection and surface testing of electronic parts.

- Understand how to perform the tests.

- Understand the criteria for acceptance and rejection.

- Understand the general format of the test report for external visual inspection.

- Assess additional considerations including equipment needed, equipment cost, training and outsourcing options.

The class is best suited for individuals with quality, inspection and testing, purchasing, and sales responsibilities. Students taking TM-02 are expected to have a working knowledge of what a counterfeit part is and where counterfeit parts come from. If you do not have sufficient background knowledge, InterCEPT recommends completion of CF-01: A Historical Overview of Counterfeit Electronic Part Activity: The Risk, Response, and Solution.

This class will be added shortly to InterCEPT’s class offerings addressing the detection of counterfeit electronic components.

Click here to sign up for notifications once the class is added.

SEE MORE BLOG ENTRIES

|

CF-02 Click to Register

ST-05 Click to Register

TM-02 Sign up for Updates

|